This machine has the advantages of high safety, fast packaging speed, wide packing range and easy operation. It is a good choice for you to improve work efficiency, save working time, reduce product packaging costs, and improve product quality.

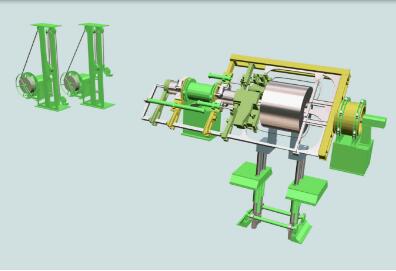

The steel coil packaging line uses machine automation to carry out a series of metallurgical industry products such as steel coils, plates, etc., including inner corner protection, plastic bag and outer wrapping paper, outer steel skin, circumferential bundling, and perforation bundling The whole set of packaging is completed, and then transported to the storage location; Widely used in sheet and coil packaging, etc.;

Main process of the packing line:

- The steel coils to be wrapped are transported to the entrance of the packaging unit by a crane or a coil transporter. The walking beam places the steel coils on a fixed saddle, and packs them with plastic or paper corners at station 1.

- The walking beam moves the steel coil to the station 2, the lifting device of the steel coil hoist rises, the steel coil is completely empty, and the paper wrapping machine wraps the anti-rust paper on the outer circumference of the steel coil. , Stick the paper head with tape, and then cover the PE plastic film into the steel coil.

- The steel coil reaches the station 3, and the operator performs the packaging operation of anti-rust paper and PE plastic film sleeve.

- The steel coil reaches the station 4, and the lifting device of the steel coil hoist rises. The operator selects the appropriate outer steel skin according to the size of the steel coil to be packaged, wraps it on the outer circumference of the steel coil, and sticks the wrapped steel with tape The skin head, the lifting device is lowered, and the steel coil is returned to the fixed saddle of station 4.

- The operator installs the end caps on both sides of the steel coil, the inner wrapping steel skin and the inner and outer guard rings.

- The full-automatic circumferential steel strapping machine performs the processes of winding, tightening, snapping, and cutting off the steel coils to automatically complete the circumferential strapping (the number of strapping channels can be according to your requirements).

- Station 7 is a reserved motorized station, which can be bundled manually.

- The automatic perforated steel strapping machine automatically completes the perforation and bundling of the steel coils for winding, tensioning, snapping, cutting and other processes (the number of strapping can be according to your requirements).

- Station 9 is the packing completion station. When the steel coil arrives at this station, the computer confirms the completion of the steel coil packing, prints out the barcode of the outer package, and the walking beam advances to the front limit, and sends out the coiling instruction to the coil carrier.

- Station 10-14 is a coil storage station. The finished steel coils can be temporarily stored in these stations, saving time for crane hoisting. After the coil carrier receives the coiling instruction, it will advance to 9 Working position, hold up the steel coil, and move the coil carrier back to a storage space far away from you, place the steel coil on the storage position, and return to the waiting position.

- When the steel coils in the coil storage position are stored to a certain amount, use the crane to lift the steel coils into the warehouse.