The working process of the sleeve-type automatic shrink wrapping machine is composed of three parts: the mechanical system, the electrical system, and the air system. This machine is a relatively newly designed packaging equipment among the sleeve-type sleeve film sealing and cutting heat shrink packaging machines. This shrink wrapper is mainly used for beverage bundles, carton, bottled water and other large items for film sealing and cutting packaging. The suitable packaging material for this machine is PE film, which greatly saves the packaging cost compared with the traditional carton packaging. It is used in conjunction with the jet heat shrinking machine to make the package achieve complete and good shrinking effect.

After the product is sealed and cut, it directly enters the shrink tunnel to complete the packaging, which greatly improves the work efficiency and reduces the power consumption. The main electrical parts of the sleeve shrink wrap machine are imported high-quality components, and the action execution part is made of high-quality pneumatic components, so the operation becomes extremely simple, the performance is very stable, the failure rate is extremely low, and the service life is longer. It can work continuously for a long time and can meet the needs of mass production. It is suitable for bottomless (or with half tray) heat shrinkable packaging of cans, mineral water, beer, glass bottles, beverages and other bottled products; at the same time, it is used in conjunction with a constant temperature PE shrinking oven to achieve a satisfactory packaging effect for the used items.

Machine’s Advantages:

·Specially designed for the automatic packaging production line of beer, beverage, pure water, fruit juice, dairy products and other beverages.

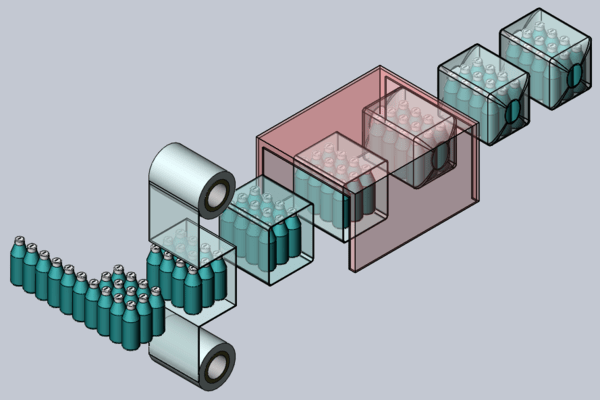

·It has the fully automatic function of feeding, unscrambling, film wrapping, sealing and cutting, shrinking, cooling and shaping.

·The heat shrinking machine adopts the world’s advanced film constant temperature heat sealing technology, and the seal is clear and firm. Suitable for pe heat shrinkable film.

·Sealing rapid cooling structure ensures higher sealing strength under high-speed production conditions.

·Digital temperature control, more stable control. Adopt PLC program automatic cycle control, stable and reliable performance.

·The original imported guide rod cylinder ensures accurate movement. Durable.

·Sensor switch controls the film feeding system, reliably adjusts the film feeding length and reduces loss.

·Frequency conversion speed regulation, stable transmission. All transmission is frequency conversion speed regulation, and the transmission is smooth and smooth.

·Conveyor can be designed as mesh conveyor or roller conveyor according to customer’s requirements, reinforced conveying motor to ensure smooth conveying.

·Quartz far-infrared tube heating, energy saving, good shrinkage effect. Unique heat shrinking channel, two sets of centrifugal hot air circulation system, even heat balance, shrink tight, beautiful.

·Integrated design of automatic conveying, technology, alignment, film feeding, sealing and cutting, shrinking and cooling, and alignment can be made according to customer requirements.

·Increased lane sorting device and counting sensor, can pack multi-column collective packing without paper pallets.

Technical Features:

- The upper and lower power supply is controlled by inductive proximity switches, which can effectively prevent miscutting the packaging and ensure the safety of the operation;

- High-performance Omron PLC plays a key role in the stable and reliable operation of the whole machine;

- The perfect combination of Omron AC contactor and high-power solid-state adjustment, together with intelligent instruments, makes the system temperature more accurate and greatly prolongs the service life;

- The high-power continuously variable transmission system ensures the conveying quality;

- The upper and lower hot air circulation system ensures perfect packaging effect at one time. High-power cooling air motor, strong cooling effect is good;

- Set up PID temperature controller, the temperature control can save energy, and the performance of the temperature controller can be good;

- The equipment passes through the automatic control system, the production process is stable and reliable, and can adapt to long-term work without stopping;

- Adopt PLC programmable control system to ensure the accuracy and stability of packaging process control;

- All the conveying chain rollers are made of solid rollers, and the outside is covered with silica gel, which can bear heavy objects and the shrink film is not easy to burn;

- Applicable to the shrinkage of various films, especially PE film.