Stretch wrapping machine is divided into conventional post stretch type and pre-stretch type based on the different structures of the film carriage. The conventional post stretch film carriage mainly relies on the tension between the wrapped object itself and the film carriage(wrap head) to extend the stretch film and wrap it on the object. Conventional post stretch film carriage is often to see on orbital stretch wrap machine, coil wrapper and some low price pallet stretch wrapping machines.

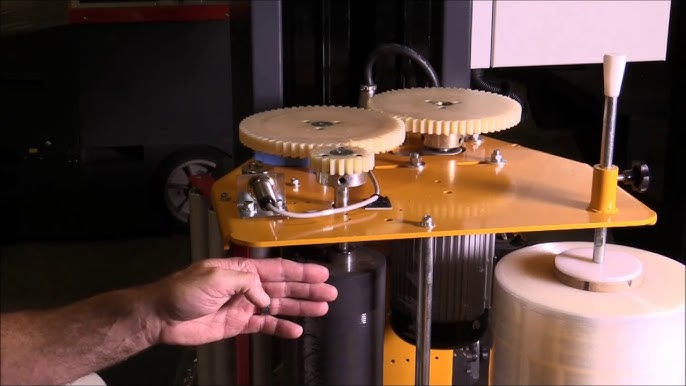

The pre-stretch film carriage uses a different structure with rollers inside the film carriage to stretch the wrapping film through the difference in rotation speed of the rollers, and then wrap it around the object to achieve the pre-stretch wrapping operation. The pre-stretch film carriage is used the most on pallet stretch wrapping machine.

So, what are the advantages of pre-stretch film wrapping machines when compare with post stretch film wrapping machines?

Advantages of Pre-stretch Film Wrapping Machine:

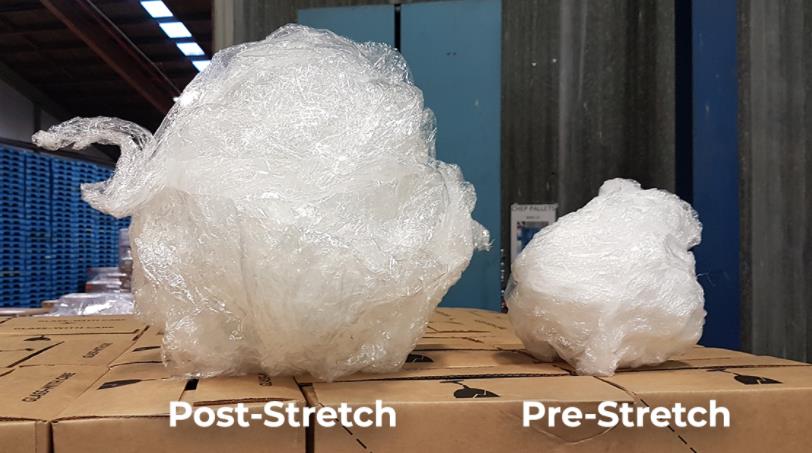

- Good packaging effect. The pre-stretch film carriage makes better stretching and has higher stretch ratio, so the wrapped package is in a tighter condition than the package done by conventional post stretch film carriage. This is because the stretched film will drawback 1 minute after the stretch, making the package become tighter and improve its loadability.

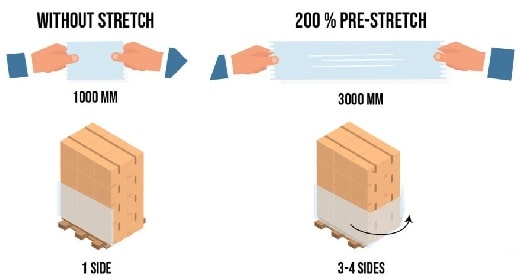

- Save stretch film. As we all know, stretch film is a consumable material for the stretch wrapping machine. Its consumption determines the packaging cost of the company. Due to its special structure of the film carriage, the pre-stretch film wrapping machine can stretch the stretch film at a ratio of 200-400%. Extending the stretch film from the original 1 meter to 2-4 meters, greatly saving packaging costs.

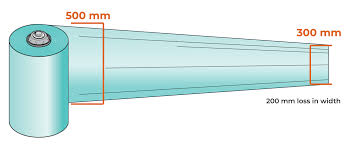

- Effective film spreading. We have introduced before that the post stretch film wrapping machine relies on the force of the wrapped object itself to stretch the film. However, the disadvantage of this method is that the original 500mm width of the film is only 300mm or less when it is actually wrapped around the object. Becoming much narrower after the stretch motion. The pre-stretched film carriage uses its unique active and driven roller system to spread the film well and maintain the original width to wrap around the object, no loss in width.

- Wide application range. Since the post stretch film carriage is wrapped by the force of the wrapped object itself, it cannot used to package lighter items, but the pre-stretch film carriage can, and even for irregular items the pre-stretch film carriage will have a good packaging effect. Therefore, in terms of scope of application, the pre-stretch film carriage also has obvious advantages.