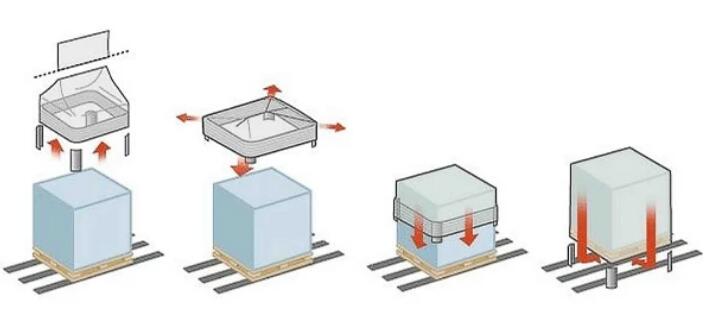

Stretch hood is an efficient all-in-one packaging method that is more sustainable, has lower operating costs and uses less energy. It is pulled open from four angles by the stretch hooder, covering the entire loads from top to bottom, with high elasticity and high clamping force. Excellent tear and puncture resistance, superior clamping and stretching capabilities.

Features of Stretch Hood Packaging:

- Made from high-quality resin materials and reasonable formulas, suitable for packaging different products and goods;

- Excellent resilience and high clamping force ensure stable loading;

- Excellent ductility, puncture resistance and tear resistance;

- Good transparency, making it easier to scan the barcode of the content inside;

- Excellent performance in both high and low temperature environments;

- Times extended stretch provides longer length, easier work, lower cost and greater value;

- Unique five-sided wrapping, better waterproof performance. Packaged goods can be stacked directly outdoors, saving storage space and costs.

Pallet Stretch Hood Machine

The customized stretch hood machine uses high-precision components such as servo motors and rodless cylinders, and adopts a modular production and installation mode. After long-term and high-frequency operation test, the stretch hood machine is a high-quality packaging equipment. By adjusting the packaging speed and increasing the clamping capacity, the goods on the pallet can be better protected. Once the film reaches the bottom of the pallets, the “fingers” will break away from the film, holding the film underneath the pallets.

Applications of Pallet Stretch Hood Machine in Various Industries

The glass bottle industry adopts stretch hood packaging technology; It effectively avoids the safety risks of using natural gas for heating and the disadvantages of weak packaging and easy loosening. It improves automation efficiency and provides support for the efficient operation of glass bottle palletizers. Super strong wrapping force ensures the safety of transportation of goods.

The beverage and can-making industry uses stretch hood packaging technology; It effectively avoids the shortcomings of stretch wrap film such as poor sealing, unsealed top, and poor packaging stability. The many advantages of stretch hood packaging make this technology an ideal packaging technology for the beverage industry, best solution.

Building materials and mortar industry; Used in bricks, tiles, cement, roofing materials, mud, and even wooden floors and wall panels. These products have an increasing demand for terminal palletizing packaging, which puts forward higher requirements for packaging flexibility. Stretch hood packaging provides optimal pallet stability.

Chemical industry; Heat shrink wrapping has always been the first choice for chemical product packaging, while stretch hood packaging does not require heating of the goods and does not use heat sources, thereby avoiding the heat generated during the packaging process from affecting the quality and stability of chemical products. Avoid safety accidents.

The food industry adopts stretch hood packaging method; Individually packaged food can be directly stacked on pallets and then packaged by stretch hood. After the goods arrive at the supermarket, they can be sold after opening the packaging film. At the same time, stretch hood can provide high pallet loading stability, excellent cargo protection and optimal product visual effects.

4 Replies to “What is Stretch Hood and How It Packs the Palletized loads?”

Comments are closed.