Roller conveyors are suitable for conveying various types of goods such as boxes, bags, and pallets. They are widely used in airports, ports, coal mining and other logistics processing systems. They are generally composed of racks, rollers, roller brackets, and drive parts Composition, and can transport a single piece of heavy material and bear a large impact load, has the characteristics of large transport capacity, fast speed, light operation, and can realize multi-variety collinear shunt transport. The pulley is a cylindrical component that drives the conveyor belt. The structure of the roller can be divided into motorized roller and unmanned roller according to the driving mode. The structure of the unmanned roller has the advantages of simple structure, high reliability, easy installation, and convenient use and maintenance.

At present, the common installation method of the roller is fixedly connecting the roller shaft with the brackets on both sides of the roller. Generally, the following two methods are adopted: one is the axial fixed installation between the roller body and the shaft, and the roller shaft and the brackets on both sides are fixed by fasteners. If the length of the shaft is greater than the distance between the brackets and the brackets, and The brackets on both sides are fixed, which makes it impossible to install; another installation method is the separate installation of the rolling cylinder and the shaft. One end of the shaft first penetrates the inner hole of the bracket and moves axially on the side of the inner hole opened by the bracket. Until the other end of the shaft penetrates another bracket hole, and then fix the roller shaft axially through the pin shaft, the installation is difficult and the installation efficiency is low. Since the shaft only adopts a radial fixing structure, during the operation of the roller, when the pin shaft fails , the shaft is easy to separate from the roller, which makes the operation of the roller invalid, and it is easy to fall, which poses a safety hazard.

The above two installation methods all have the disadvantages of complicated and difficult installation and low installation efficiency.

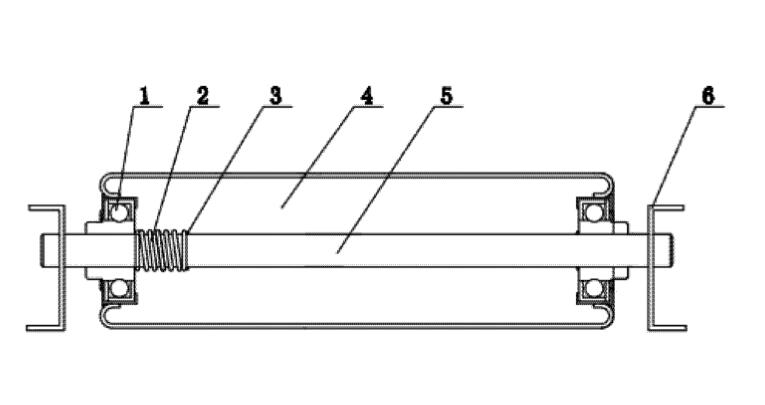

This is a spring-loaded roller, including a roller body, a roller shaft and bearings. The roller shaft runs through the center of the roller. Bearings are respectively installed between the rollers, a spring is arranged between the bearing at one end and the bump on the outer surface of the roller shaft, and the bearing at the other end is installed outside the bump on the outer surface of the other end of the roller shaft. The integrated roller shaft has a simple structure and is easy to process and manufacture. There are bumps on the roller shaft and springs are inserted into it, so that the roller shaft has a certain range of axial expansion and contraction in the axial direction. It can be installed during installation One end is indented and the other end is extended, which is convenient for the installation and positioning of the shaft. This structure provides convenience for the installation and disassembly of the roller on the bracket, avoids the problems of difficult installation in the prior art, and improves the installation efficiency.