Packaging can provide appropriate protection for furniture products, provide branding services for furniture product design, production, and sales, and ensure consumers obtain better and safer products. In today’s rapid development of panel type furniture, the study of furniture packaging is helpful to reduce the loss of enterprises in furniture transportation and sales, shorten the delivery cycle of products, and improve the satisfaction of buyers.

Generally speaking, furniture companies set up production plants in one city, and set up sales and installation outlets in multiple cities for production and sales. It is different from industrial products that can be put into use in one production. After the parts are produced, the furniture is often transported from the production site to the customers’ homes in different places, and then assembled by the installation workers at the customer’s home site. If problems such as damage to parts due to unreasonable packaging are often not found in time, it is necessary to wait for the installation of the goods to determine the damage to the parts. In the event of damage, the installer will feed back the information on the missing parts to the production department, and the production department will produce according to the “production order supplementary order” (referred to as “replenishment order”) and replace the defective goods according to the process.

Re-issuing spare parts from the production site not only takes a lot of time, but also often causes problems such as product color difference due to the mismatch between the batch of raw materials in the subsequent replenishment order and the original order. This will not only bring losses in production and transportation to enterprises, but also affect the delivery schedule of products and bring inconvenience and bad experience to customers. In addition, furniture products transported to the site often need to be stored in the warehouse or stored on site for a period of time. If the corner joints of the furniture panels are not closed, there will be hidden dangers of mildew in the cabinet caused by the damping of the panels. . Therefore, it is very important to study the packaging of furniture.

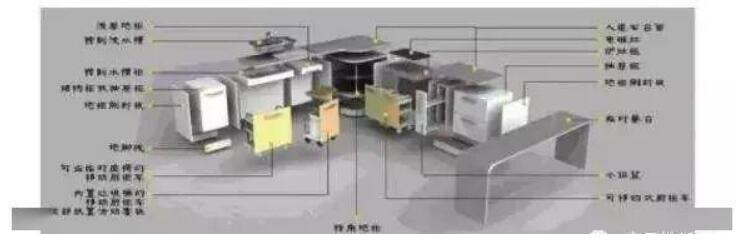

Take kitchen furniture as an example (tables, beds, chairs, sofas, cabinets, etc. are similar): the main components of panel furniture are shown in Figure, which can be roughly divided into cabinet (box) packaging, There are several main categories such as board packaging, wire board packaging, countertop packaging, hardware accessories packaging and electrical packaging. Several categories of components each have their own characteristics.

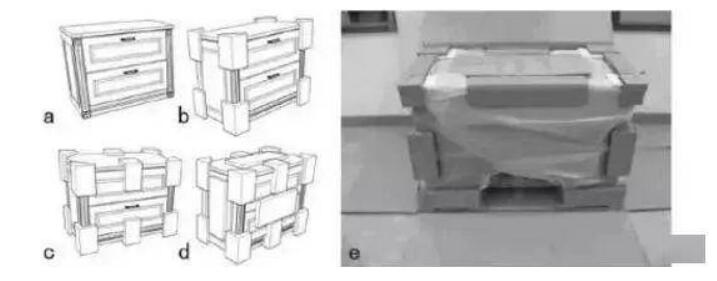

Most of the cabinets and cabinets are relatively regular in shape and suitable for packing. Generally, it is wrapped with edge and corner protection material and pearl cotton, and then made of corrugated paper into an outer packaging carton for packaging. Door panels, side panels, and the packaging of mountain panels, partitions, etc. that are not assembled into cabinets can all be called panel packaging. Because there are many kitchen cabinet side panels with the same specifications (the rows of holes are different), the same type of panels can be packaged together during packaging. Various lengths of slender parts such as anchor lines and eyebrow lines are generally made of corrugated paper flexibly according to the length of the line board. Or use an outside-sealed carton to pack slender furniture parts.

The countertop is an important part of furniture. Compared with other parts, the volume and quality are large and need to be packaged separately. Hardware is mostly packaged in matching carton boxes, and a set of cabinets generally has a dedicated hardware box.