How does industrial automation work in the packaging process?

The highly automated machines has the function of carried out the work process by itself under unmanned operation. It’s the integration of programmable control system units, electro-mechanical, electro-pneumatic and electro-hydraulic systems. The whole packaging system is aimed to be effective, accurate and efficient.

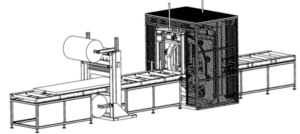

The furniture packaging machine has the state of art design and automatic operation system and it’s specialized to make the package for furniture and in a fully automatic way.

The advantages of the automation process in furniture packaging

The automatic furniture packaging machine has considered many aspects when doing the design. And this includes the shape of furniture, the accessories and the dimensions and weight of the door and windows…… All these make this machine is the most suitable and fitted machine for your furniture packaging.

Automated packaging is synonymous with efficiency and effectiveness

The target of using the automated packaging machine is to improve the efficiency of the whole production. Which simply is to make as more products in the shorter time and using costs as less as possible. The whole automated process will enable we make accurate calculation and control the whole flow of the production and logistic.

The automatic packaging machine not just reduces the amount of labour costs than using the manual packaging ways. It also reduces the damage to the goods and make the packaging more uniformed and has better quality. One of the another advantages of the automatic packaging machine is that it can reduce the workload for the operators. And the automatic working mode made the operator no need to have constant attention to the packaging machine. They can devote their time and emergy to other work as the packaging machine is working with them simultaneously.

A clear example of automation: our furniture packaging machine

Our automated furniture packaging machine is carried out in two processes. First, the machine will create a bubble film bag which to pack the product. Then, this bag will be wrapped with stretch film, leaving the product to be packed perfectly protected from the outside. The product is then placed centred on the in-feed conveyor table and the packaging process starts automatically.

This automated process reduces the possibility of wastage of packaging materials. By pre-setting the parameters of power, speed, precision and position, the time and quantity of wrapping material used can be measured.

Thanks to the increased productivity, reduced waste and the lowest possible consumption of packaging material, all these will contribute to the costs saving eventually. There are enough reasons to upgrade for automation in a furniture packaging plant.