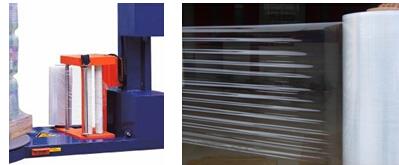

The pallet wrapper machine can be widely used in all walks of life. The cargo are packed on the pallet with LLDPE stretch film to make the goods stable, tidy and convenient for transportation. In addition, it also has the function of waterproof and dustproof. It can also greatly reduce labor intensity and improve work efficiency. It is an ideal packaging equipment for modern enterprises.

The main parameters:

- The electrical control adopts PLC.

- Special packaging position reinforcement can be set randomly, and it can be automatically reset.

- Automatic working mode. It can also be changed to manual mode.

- The indicator lamp will alarm automatically.

- Photoelectric detection of tray height.

- Tension is controlled by electromagnetic controller.

- Simple design, easy to operate and maintain.

- Manual operation, flexible and economical.

- Can start, stop and reset freely.

- The packaging position can be set freely for reinforcement.

Top press platen: For very high or very light pallets, the goods on the pallet are easy to fall when the turntable rotates. The top press plate is used to press the top of the pallet to fix the position and prevent the goods from falling and moving.

Pre-stretching device: Pre-stretching refers to pre-stretching the film before packaging the object. When used in light weight or high packaging, it can ensure stability. It can keep the tray stable during the packaging process. It can also save 30-50% of the film than usual.

ACCESS RAMP: Used to conveniently load and unload pallets when transported by a manual forklift. It is not necessary when loading with an electric forklift.